Engineering Services & Development Capabilities

At Cornet Technology India, we don’t just manufacture rugged boards—we engineer solutions. From concept design to long-term support, we provide end-to-end services tailored to the defense, aerospace, and mission-critical sectors. Whether it’s customizing a COTS board, integrating firmware into your system, or building a full ATR system for your platform—we’ve got it covered.

Our Engineering Approach

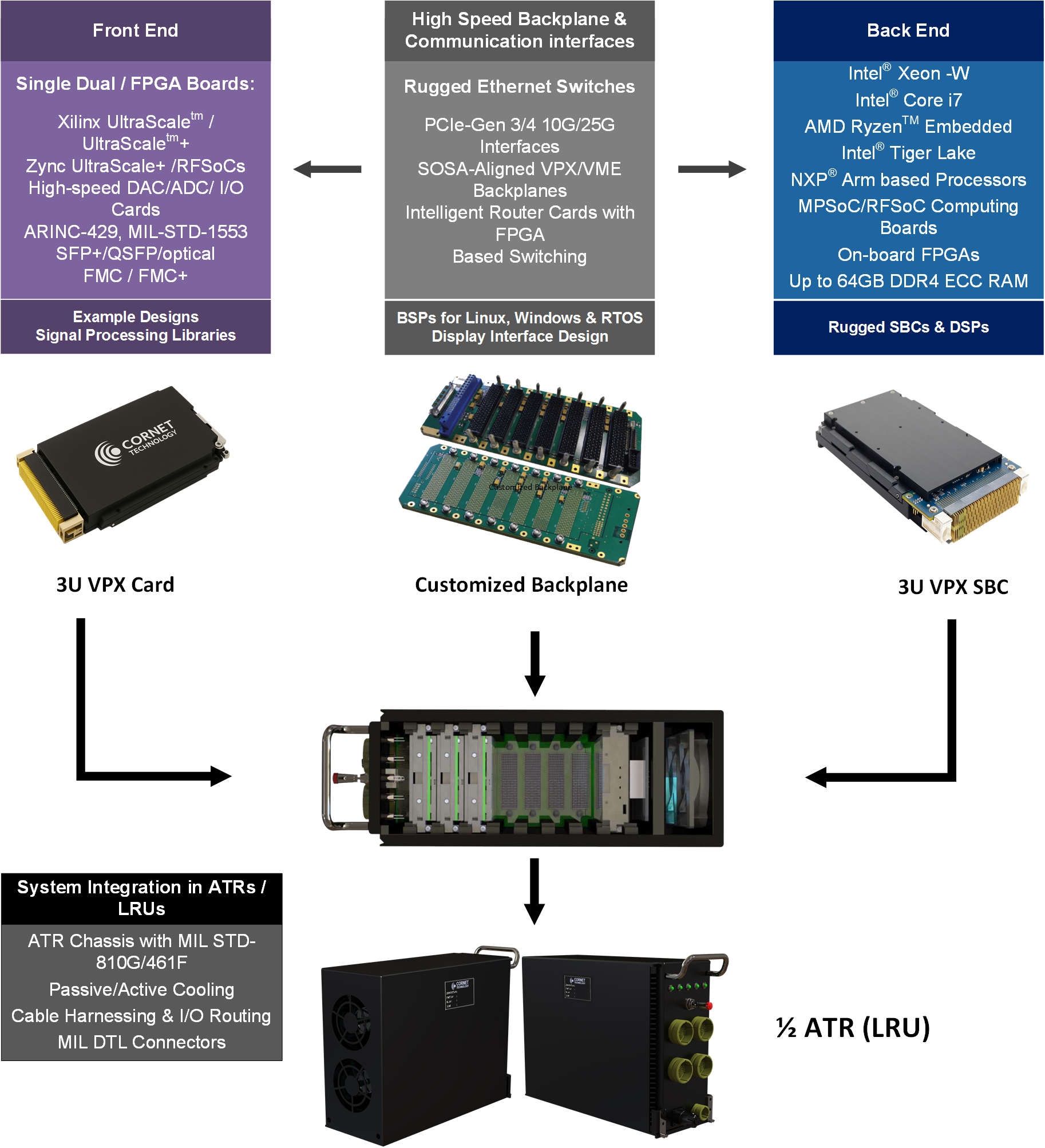

Empowering Customized COTS Embedded Solutions for Mission-Critical Applications

Cornet Technology India designs, develops, and supports high-performance embedded computing systems tailored for defense, aerospace, and industrial use cases. With decades of experience and a proven track record in the Indian defense ecosystem, we deliver customizable, ruggedized solutions that meet demanding operational requirements and accelerate deployment timelines.

Our engineering excellence spans the full product lifecycle—from requirement analysis to obsolescence management – under one roof. Every product is developed and tested in India, in line with the “Make in India” initiative and with support for global OEMs looking to localize.

-

Requirement Analysis :

Collaborative understanding of customer needs across defense, aerospace, and critical infrastructure sectors

- Architecture Proposal :

From Commercial Off-The-Shelf to Modified COTS (MCOTS) and fully custom solutions - Hardware and Software Design :

In-house expertise in embedded board design, FPGA development, and BSP/driver engineering - Modular Building Blocks :Comprehensive product portfolio:

SBCs, mission computers, ATRs, network switches, I/O cards, DAQ systems, and display consoles

-

Prototyping and Qualification :

Accelerated prototyping and MIL-STD environmental qualification support

-

Customer Support :

Dedicated engineering and field teams ensure seamless integration and deployment

-

Lifecycle & obsolescence management :

Long-term availability planning and obsolescence support tailored to defense timelines

Resources to manufacture quality state-of-the-art COTS and custom products

- Sourcing Excellence

All components and PCBs are sourced from vetted, approved vendors in alignment with detailed Bill of Materials (BoM), ensuring quality, traceability, and long-term availability. - High-Reliability Assembly

Our embedded boards are assembled following robust internal procedures aligned with IPC-A-610 Class 3 workmanship standards, suited for mission-critical and defense-grade electronics. - Inline Process Control

Each stage of the manufacturing lifecycle is subject to rigorous inspection, including automated optical checks and manual quality gates to maintain production consistency. - Functional Validation

Every board undergoes thorough functional testing using validated test jigs and procedures tailored to customer requirements and product configurations. - Environmental Screening & Final Integration

Upon conformal coating and mechanical assembly, boards may be subjected to environmental stress screening (ESS) such as thermal cycling and vibration tests as per MIL standards and project-grade specifications – available on request.

Engineering Services

Concept to Qualification — Embedded, Rugged, and Mission‑Ready

Product Design & System Engineering

- Product design specifications

- System architecture & trade studies

- Prototyping & design reviews

Embedded Software & Firmware

- Board support packages (BSP)

- Real‑time OS, device drivers, middleware

- Firmware bring‑up & diagnostics

- Audio/Video pipelines

Board & Hardware Design

- High‑speed digital & mixed‑signal

- RF & antenna design

- Power supply design

- Hardware board design services

Industrial & Ruggedized Designs

- Thermal, shock & vibration considerations

- Environmental & EMI/EMC engineering

- Ruggedization for defense/avionics

FPGA & DSP / RADAR

- FPGA design & verification

- Signal & image processing

- RADAR/sonar algorithm integration

Verification, Validation & Certification

- DO‑178C / DO‑254 / DO‑160 support

- FCC/CE/IEC compliance & testing

- Test plans, procedures & traceability

Production & Lifecycle Support

- PCB design & library management

- Production support & NPI

- Obsolescence & lifecycle management

FPGA Design, Integration & IP Core Support

Cornet India provides robust FPGA design and integration services tailored for mission-critical Defense and Aerospace systems. Our expertise spans across:

-

Board bring-up and validation for FPGA-based SBCs & subsystems

-

Custom firmware development and HDL integration for VPX, VME, and COTS platforms

-

System-level FPGA customization based on program-specific I/O, timing, and interface needs

-

Delivery and support of essential IP cores including high-speed serial protocols, data interfaces, and control logic

Our engineering team ensures tight integration between FPGA, CPU, and peripheral subsystems — delivering optimized, ruggedized solutions that meet stringent performance and reliability standards

FPGA Design

Our Resources

To comply with the most stringent requirements of today’s HPEC market, Cornet India has developed expertise in thermomechanical simulation and signal integrity simulation/analysis. With this know-how, Cornet India has the capacity to develop and test extremely complex & very high-density boards and systems:

Development Software:

- PCB Altium Designer

- Cadence

Measuring equipment and instruments:

- High-Performance Oscilloscopes

- Digital and analog signal analysers

- Spirent Test Center

- 45 GHz vector network analyzer (VNA)

- High-performance signal generators

Simulation Capabilities

- Cornet India provides advanced simulation support including thermal, power integrity, and signal integrity analysis at the board level, and thermal and structural analysis at the subsystem level.

- These simulations ensure optimal performance, reliability, and compliance with defense and aerospace standards.

Cornet India supplies a full set of development tools and highly responsive technical support, to build successful solutions:

Our Grades

(*) Temperature grade options depend on semiconductor availability. Please contact us for compatibility and lead times.

| Standard | Extended | Rugged | Conduction-cooled 71°C | Conduction-cooled 85°C | |

| Coating | Optional | Yes | Yes | Yes | Yes |

| Operat. Temp. | 0 to 55°C | -20 to 65°C | -40°C to 71°C (*) | -40°C to 71°C at the thermal interface (*) | -40°C to 85°C at the thermal interface (*) |

| Rec. airflow | 1 .. 2 m/s | 2 .. 3 m/s | 2 .. 5 m/s | – | – |

| Oper. HR% no cond. | 5 to 90% | 5 to 95% | 5 to 95% | 5 to 95% | 5 to 95% |

| Storage Temp. | -45°C to 85°C | -45°C to 85°C | -45°C to 100°C | -45°C to 100°C | -45°C to 100°C |

| Sinusoidal Vibr | 2G [20..2000]Hz | 2G [20..2000]Hz | 5G [20..2000]Hz | 5G [20..2000]Hz | 5G [20..2000]Hz |

| Random Vibr | 0.002g2 /Hz [10..2000]Hz | 0.002g2 /Hz [10..2000]Hz | 0.05g2 /Hz [10..2000]Hz | 0.1g2 /Hz [10..2000]Hz | 0.1g2 /Hz [10..2000]Hz |

| Shock 1/2 Sin. 11ms | 20G | 20G | 40G | 40G | 40G |